Weld-On-Hubs, Tipe W, WH, WM saben Bahan C20

Weld-on-Hubs

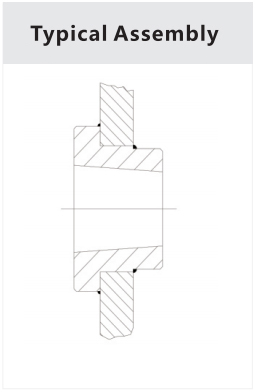

Taper Bore Weld-on-Hubs digawe saka baja, dibor, diketuk, lan dibor taper kanggo nampa Taper Bushes standar. Flensa sing dawa nyedhiyakake cara sing trep kanggo ngelas hub menyang rotor kipas, katrol baja, sprocket pelat, impeller, agitator, lan akeh piranti liyane sing kudu dipasang kanthi kenceng ing poros. Weld-on-Hubs gampang dipasang lan cocog banget kanggo digunakake ing kahanan operasi sing abot. Ngencengake xcrew bakal ngontrak bolongan bush, saengga katon menyang poros kanthi padha karo press fit. Jinis konstruksi iki ngilangi kesulitan pemasangan, uga nyegah kelonggaran lan keausan ing hub sajrone operasi. Weld-on-Hubs diprodhuksi kanggo nglengkapi kisaran Taper Bush lan kalebu W, WG, WH, WHG, WM lan WMG Taper Bore Hubs. Kabeh diprodhuksi miturut standar donya nggunakake baja C20.

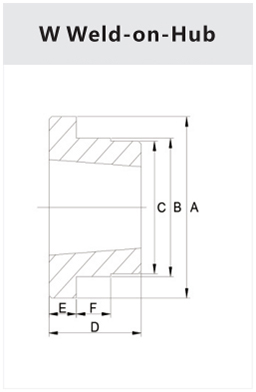

W Weld-on-Hubs

| Pusat | Ukuran Grumbulan | A | B | C | D | E | F | Fl | X |

| W12 | 1215 | 73.03 | 63.50 | 62.71 | 38.10 | 15.88 | 9.53 | - | - |

| W16 | 1615 | 82.55 | 73.03 | 72.24 | 38.10 | 15388 | 9.53 | - | - |

| W25 | 2517 | 127.00 | 111.13 | 110.34 | 44.45 | 19.05 | 12.70 | - | - |

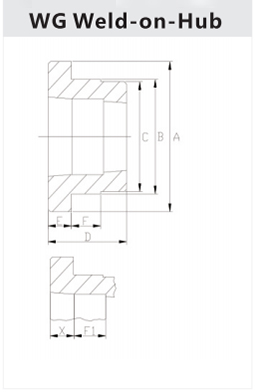

| WG30 | 3030 | 149.86 | 133.35 | 132.56 | 76.20 | 25.40 | 19.05 | 23 | 23 |

| WG35 | 3535 | 184.15 | 158.75 | 157.96 | 88.90 | 31.75 | 25.04 | 30 | 30 |

| WG40 | 4040 | 225.43 | 169.85 | 196.06 | 101.60 | 31.75 | 31.75 | 34 | 34 |

| WG45 | 4545 | 254.00 | 222.25 | 221.46 | 114.30 | 38.10 | 38.10 | 38 | 38 |

| WG50 | 5050 | 267.00 | 241.00 | 240.25 | 127.00 | 38.10 | 38.10 | 42 | 42 |

| WG60 | 6060 | 375.00 | 343.00 | 342.00 | 127.00 | 38.10 | 38.10 | 42 | 42 |

| WG70 | 7060 | 425.00 | 375.00 | 374.00 | 153.00 | 51.00 | 51.00 | 51 | 51 |

| WG80 | 8065 | 445.00 | 349.0 | 393.00 | 165.00 | 51.00 | 51.00 | 55 | 55 |

| WG100 | 10085 | 559.00 | 495.00 | 494.00 | 216.00 | 51.00 | 51.00 | 72 | 72 |

"G": natasi nggambarake relief pengelasan

Weld-on-Hubs

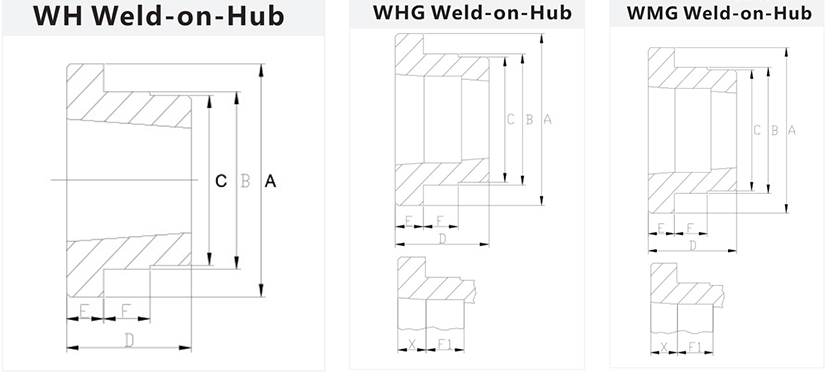

WH Weld-on-Hubs

| Referensi Hub | Ukuran Grumbulan | A | B | C | D | E | F | Fl X | |

| WH12 | 1210 | 70 | 65 | 64.5 | 25 | 9 | 10 | - | - |

| WH16-1 | 1610 | 80 | 75 | 74.5 | 25 | 9 | 10 | - | - |

| WH20 | 2012 | 95 | 90 | 89.5 | 32 | 12 | 12 | - | - |

| WH25 | 2517 | 115 | 110 | 109.5 | 44 | 19 | 15 | - | - |

| WHG30-2 | 3020 | 145 | 140 | 139.5 | 50 | 20 | 15 | 17 | 17 |

| WHG35 | 3525 | 190 | 180 | 179.5 | 65 | 25 | 25 | 22 | 22 |

| WHG40-1 | 4030 | 200 | 190 | 189.0 | 76 | 32 | 30 | 25 | 25 |

| WHG40-2 | 4040 | 200 | 190 | 189.0 | 101 | 32 | 30 | 34 | 34 |

| WHG45-1 | 4535 | 210 | 200 | 199.5 | 89 | 40 | 30 | 30 | 30 |

| WHG45-2 | 4545 | 210 | 200 | 199.5 | 114 | 40 | 30 | 38 | 38 |

| WHG50-1 | 5040 | 230 | 220 | 219.5 | 102 | 40 | 35 | 34 | 34 |

| WHG50-2 | 5050 | 230 | 220 | 219.5 | 127 | 40 | 35 | 42 | 42 |

"GH": natasi nggambarake relief pengelasan

WMG Weld-on-Hub

| Referensi Hub | Ukuran Grumbulan | A | B | C | D | E | F | Fl | X |

| WMG12 | 1210 | 70 | 60 | 58 | 26 | 9 | 10 | 9 | 9 |

| WMG16-1 | 1610 | 83 | 70 | 68 | 26 | 9 | 10 | 9 | 9 |

| WMG16-1 | 1615 | 83 | 70 | 68 | 38 | 16 | 11 | 13 | 13 |

| WMG20 | 2012 | 95 | 90 | 88 | 32 | 12 | 12 | 11 | 11 |

| WMG25 | 2517 | 127 | 110 | 108 | 44 | 19 | 13 | 15 | 15 |

| WMG30-2 | 3020 | 150 | 130 | 125 | 50 | 20 | 15 | 17 | 17 |

| WMG30-3 | 3030 | 150 | 130 | 125 | 76 | 25 | 19 | 25 | 25 |

| WMG35 | 3535 | 184 | 155 | 151 | 89 | 32 | 25 | 30 | 30 |

| WMG40 | 4040 | 225 | 195 | 187 | 102 | 32 | 32 | 34 | 34 |

| WMG45 | 4545 | 254 | 220 | 213 | 114 | 38 | 38 | 38 | 38 |

| WMG50 | 5050 | 276 | 242 | 228 | 127 | 38 | 38 | 42 | 42 |

Weld-on-hub digawe saka baja C20 lan dibor, diketok, lan dikon kanggo nampung bushing kunci sing meruncing. Iki bisa digunakake kanggo ngelas menyang katrol, sprocket, kopling, rotor kipas, roda sabuk, lan liya-liyane. Komponen kasebut kudu dipasang kanthi aman ing poros. Ana patang jinis weld-on-hub sing kasedhiya ing rak. Jinis: W, WG, WH, WHG, WM, WMG taper bore hubs.