Rantai Kacepetan Variabel, kalebu Rantai Kacepetan Variabel Tanpa Wates Tipe PIV/Roller

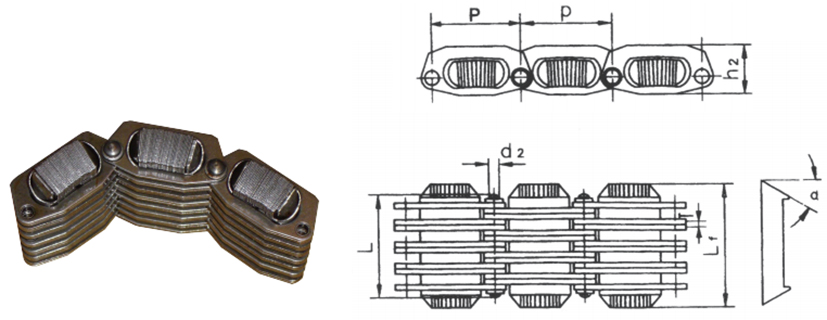

Rantai Kecepatan Variabel Tanpa Batas PIV

| GL Nomer Kdn. | Pith P mm | Diameter pin. d2(maks) mm | Dawane pin L(maks) mm | Ambane pelat h2. (maks) mm | Kekandelan pelat T(maks) mm | Kekandelan pelat T(maks) mm | Amba ing ndhuwur pelat gesekan sak derajat | Kekuwatan tarik pungkasan Q (min) Kn | Bobot saben meter kg/m² |

| AO | 18.75 | 3.00 | 19.50 | 9.50 | 1.0 | 24.00 | 15 | 9.0 | 1.0 |

| Al | 19.00 | 3.00 | 19.50 | 10.60 | 1.5 | 30.44 | 15 | 9.0 | 1.0 |

| A2 | 25.00 | 3.00 | 30.10 | 13.50 | 1.5 | 37.80 | 15 | 21.0 | 2.0 |

| A3 | 28.60 | 3.00 | 35.30 | 16.00 | 1.5 | 44.20 | 15 | 38.5 | 3.0 |

| A4 | 36.00 | 4.00 | 48.50 | 20.50 | 1.5 | 58.50 | 15 | 61.5 | 5.4 |

| A5 | 36.00 | 4.00 | 60.50 | 20.50 | 1.5 | 70.00 | 15 | 71.0 | 6.7 |

| A6 | 44.40 | 5.40 | 70.00 | 23.70 | 1.5 | 77.00 | 15 | 125.0 | 9.0 |

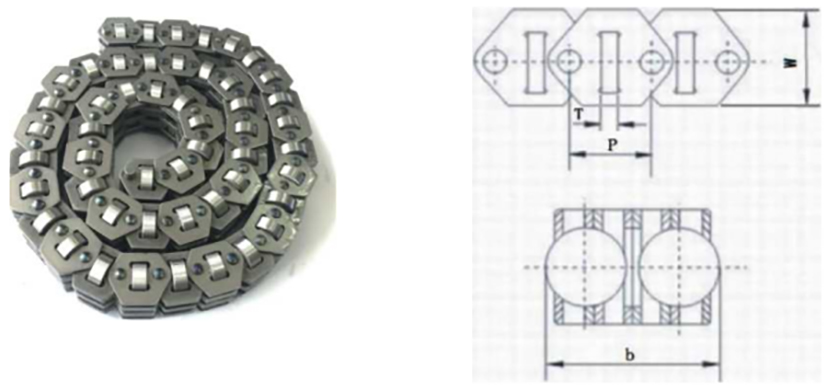

JENIS ROLLER RANTAI KACEPATAN VARIABEL INTENIMAL

| GL RANTAI NO. | PITCH | PLAT Dhuwur | Roller Ambane | Roller KEKANCANGAN |

| P | W | b(menit) | T (maks) | |

| mm | mm | mm | mm | |

| RBO (Residen Berbasis Otomotif) | 10.10 | 923 | 12.00 | 2.90 |

| RBI (Register of Business) | 1220 | 12.30 | 16.04 | 4.10 |

| RB2 | 14.66 | 14.80 | 20.00 | 4.74 |

| RB3 | 12.60 | 16.60 | 24.60 | 4.70 |

| RB4 | 14.00 | 20.70 | 31.00 | 5.50 |

| RC3 | 1320 | 18.80 | 24.54 | 4.70 |

| RC4 | 1620 | 22.50 | 31.00 | 5.30 |

Rantai Kecepatan Variabel kanggo Kotak Gir

1. Rantai kecepatan variabel tanpa wates PIV:

A0, A1, A2, A3, A4, A5, A6

2. Rantai kecepatan variabel tanpa wates jinis roller:

PSR1, PSR4, PSR5, RB0, RB1, RB2, RB3, RB4, RC3, RC4 lan liya-liyane.

Fungsi: Nalika owah-owahan input njaga kecepatan rotasi output sing luwih stabil. Produk digawe saka produksi baja paduan kualitas dhuwur. Pelat-pelat kasebut dilubangi lan dipencet nganggo teknologi presisi. Pin, bush, roller dimesin nganggo peralatan otomatis efisiensi dhuwur lan peralatan penggilingan otomatis, banjur liwat perawatan panas karburisasi, tungku sabuk bolong perlindungan karbon lan nitrogen, proses peledakan permukaan, lan liya-liyane. Dirakit kanthi presisi kanthi posisi bolongan internal, puteran dipaku nganggo tekanan kanggo njamin kinerja kabeh rantai.