Kopling Oldham, Badan AL, Elastis PA66

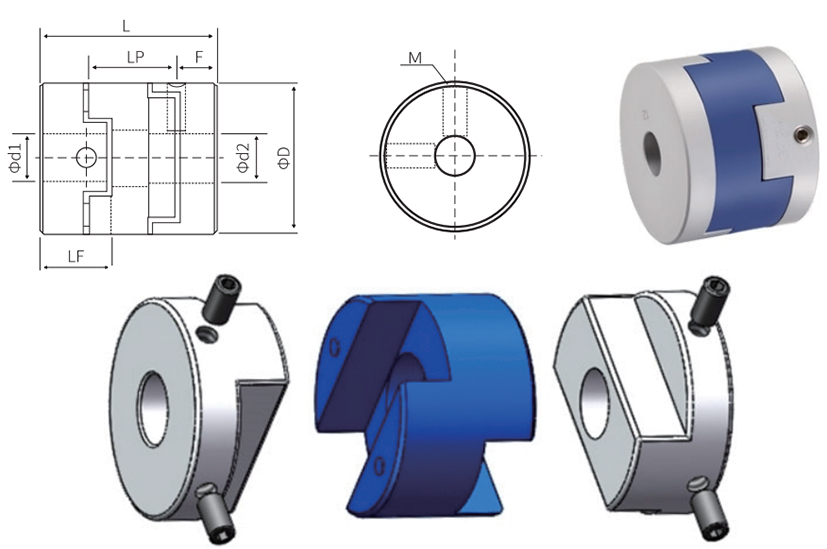

| Tabel ukuran | mm | |||||||

| Model | Ukuran diameter njero DL / D2 umum | ΦD | L | LF | LP | F | M | Torsi tightening (nm) |

| GL-16X18 | 4-5-6-6.35-7-8 | 16 | 18 | 7.1 | 12 | 3.0 | M3 | 1.2 |

| GL-20X23 | 5-6-6.35-7-8 | 20 | 23 | 9 | 12.7 | 4.5 | M4 | 1.7 |

| GL-20X25 | 5-6-6.35-8-9-9.525-10 | 20 | 25 | 10.1 | 12.7 | 3.0 | M4 | 2.5 |

| GL-25X28 | 5-6-8-9-9.525-10-11-12-14 | 25 | 28 | 21 | 17.7 | 2.8 | M4 | 2.5 |

| GL-32X33 | 5-6-8-9-9.525-10-11-12-12.7-14-15-16 | 32 | 33 | 14 | 20 | 3.4 | M4 | 2.5 |

| GL-40X32 | 8-9-9.525-10-11-12-12.7-14-15-16-17-18-19-20 | 40 | 32 | 14 | 20.3 | 3.2 | M4 | 2.5 |

| GL-44X46 | 8-9-9.525-10-11-1212.7-14-15-16-17-18-19-20-22 | 44 | 46 | 20.7 | 18.4 | 3.5 | M5 | 5 |

| GL-50X38 | 10-12-12.7-14-15-16-17-18-19-20-22-24-25 | 50 | 38 | 16.5 | 22.35 | 3.8 | M5 | 5 |

| GL-55X57 | 10-12-12.7-14-15-16-17-18-19-20-22-24-25-28-30-32 | 55 | 57 | 26.2 | 25.8 | 7.8 | M5 | 5 |

| GL-63X47 | 14-15-16-17-18-19-20-22-24-25-28-30-32 | 63 | 47 | 21 | 25.8 | 6.0 | M6 | 8 |

| GL-70X77 | 16-17-18-19-20-22-24-25-28-30-32-25-38-40 | 70 | 77 | 37 | 25 | 13.5 | M8 | 20 |

Parameter teknis

| Parameter teknis | mm | |||||||

| Model | Dirating torsi (Nm) | Eksentrisitas sing diidini (mm) | Sudut defleksi sing diidini (∠.) | Panyimpangan aksial sing diidini (mm) | Kacepetan sing diidini (RPM) | Kekakuan torsi statis (Nm/rad) | Momen inersia (Nm) | Bobot kopling (g) |

| GL-16X18 | 0.7 | 0.8 | 3 | ± 0.2 | 9000 | 30 | 3.0X10-7 | 6 |

| GL-20X23 | 1.2 | 1.5 | 3 | ± 0.2 | 3100 | 60 | 1.0X10-6 | 14 |

| GL-20X25 | 1.25 | 1.2 | 3 | ± 0.2 | 7000 | 58 | 3.0X10-7 | 18 |

| GL-25X28 | 2 | 1.6 | 3 | ± 0.2 | 6000 | 130 | 2.8X10-6 | 25 |

| GL-32X33 | 4.5 | 2 | 3 | ± 0.2 | 4800 | 270 | 8.9X10-5 | 44 |

| GL-40X32 | 9 | 2.4 | 3 | ± 0.2 | 3600 | 520 | 2.1X10-5 | 81 |

| GL-44X46 | 12 | 2.8 | 3 | ± 0.2 | 3500 | 560 | 3.8X10-5 | 136 |

| GL-50X38 | 19 | 2.6 | 3 | ± 0.2 | 3000 | 800 | 6.0X10-5 | 142 |

| GL-55X57 | 22 | 3.3 | 3 | ± 0.2 | 2800 | 795 | 9.9X10-5 | 255 |

| GL-63X47 | 33 | 3 | 3 | ± 0.2 | 2500 | 1200 | 2.1X10-4 | 320 |

| GL-70X77 | 56 | 3.8 | 3 | ± 0.2 | 2500 | 1260 | 3.9X10-4 | 445 |

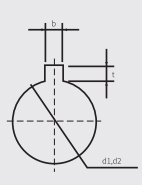

Tabel perbandingan dimensi pangolahan alur pasak

| Ukuran diameter poros | Dimensi mesin standar saka keyway | Ukuran keyway | Gambar standar pangolahan keyway | |||

| dl/d2 | b | t | (bxh) |

| ||

| jembaré Slot | toleransi | ambane slot | toleransi | |||

| Φ6-Φ7.9 | 2 | ± 0,0125 | 1.0 | ± 0,10 | 2X2 | |

| Φ8-Φ10 | 3 | ± 0,0150 | 1.4 | 3X3 | ||

| Φ10.1-Φ12 | 4 | 1.8 | 4X4 | |||

| Φ12.1-Φ17 | 5 | 2.3 | 5x5 | |||

| Φ17.1-Φ22 | 6 | ± 0,0180 | 2.8 | 6x6 | ||

| Φ22.1-Φ30 | 8 | 3.3 | ± 0,20 | 8x7 | ||

| Φ30.1-Φ38 | 10 | ± 0,0215 | 3.3 | 10X8 | ||

| Φ38.1-Φ44 | 12 | 3.8 | 12X8 | |||

| Φ44.1-Φ50 | 14 | 4.3 | 14X9 | |||

| Φ50.1-Φ58 | 16 | 4.4 | 16X10 | |||

| Φ58.1-Φ65 | 18 | 4.4 | 18X11 | |||

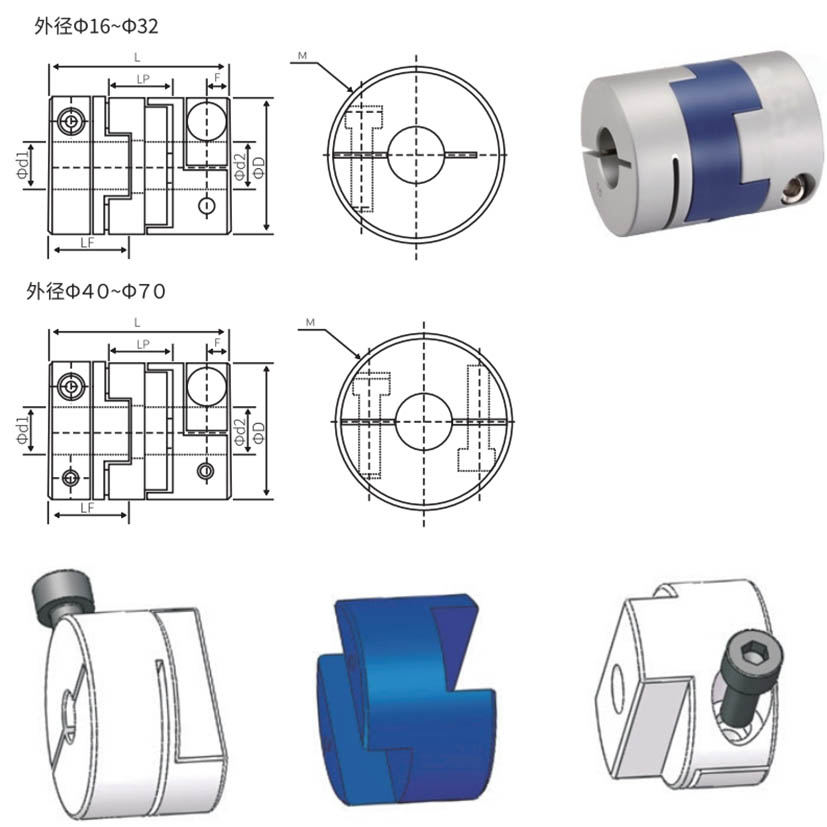

Tabel ukuran garis

| Tabel ukuran garis | mm | |||||||

| Model | Ukuran diameter njero DL / D2 umum | ΦD | L | LF | LP | F | M | Torsi tightening (nm) |

| GLC-16X29 | 4-5-6-6.35 | 16 | 29 | 12.5 | 12 | 3 | M2.5 | 0.8 |

| GLC-20X33 | 5-6-6.35-7-8 | 20 | 33 | 14.1 | 12.7 | 3.8 | M2.5 | 0.8 |

| GLC-25X39 | 5-6-6.35-8-9-9.525-10-11-12 | 25 | 39 | 16.9 | 17.7 | 3.9 | M3 | 1.2 |

| GLC-32X45 | 5-6-8-9-9.525-10-11-12-12.7-14-15-16 | 32 | 45 | 20 | 20 | 4.5 | M4 | 2.5 |

| GLC-40X50 | 8-9-9.525-10-11-12-14-15-16-17-18-19 | 40 | 50 | 23 | 20.3 | 5.5 | M5 | 5 |

| GLC-44X46 | 8-9-9.525-10-11-12-14-15-16-17-18-19-20-22 | 44 | 46 | 20.7 | 18.4 | 7 | M5 | 5 |

| GLC-50X53 | 10-11-12.7-14-15-16-17-18-19-20-22-24 | 50 | 53 | 24.2 | 22.35 | 7.5 | M6 | 8 |

| GLC-50X58 | 10-11-12.7-14-15-16-17-18-19-20-22-24 | 50 | 58 | 26.5 | 22.35 | 6.3 | M6 | 8 |

| GLC-55X57 | 10-11-12.7-14-15-16-17-18-19-20-22-24-25-28 | 55 | 57 | 26.2 | 25.8 | 6.3 | M6 | 8 |

| GLC-63X71 | 14-15-16-17-18-19-20-22-24-25-28-30-32 | 63 | 71 | 32.8 | 26.2 | 7.8 | M8 | 20 |

| GLC-70X77 | 14-15-16-17-18-19-20-22-24-25-28-30-32-35-38 | 70 | 71 | 37 | 25 | 7.7 | M8 | 20 |

Parameter teknis

| Parameter teknis | mm | ||||||||

| Model | Dirating torsi (Nm) | Eksentrisitas sing diidini (mm) | Sudut defleksi sing diidini (∠.) | Panyimpangan aksial sing diidini (mm) | Kacepetan sing diidini (RPM) | Kekakuan torsi statis (Nm/rad) | Momen inersia (Nm) | Bobot kopling (g) | |

| GLC-16X29 | 0.7 | 0.8 | 3 | ± 0.2 | 9000 | 30 | 3.5X10-7 | 12 | |

| GLC-20X33 | 1..2 | 1.2 | 3 | ± 0.2 | 7000 | 58 | 1.5X10-6 | 19 | |

| GLC-25X39 | 2 | 1.6 | 3 | ± 0.2 | 6000 | 130 | 3.2X10-6 | 35 | |

| GLC-32X45 | 4.5 | 2 | 3 | ± 0.2 | 4800 | 270 | 1.5X10-5 | 67 | |

| GLC40X50 | 9 | 2.4 | 3 | ± 0.2 | 3600 | 520 | 4.2X10-5 | 114 | |

| GLC-44X46 | 12 | 2.5 | 3 | ± 0.2 | 3500 | 800 | 4.5X10-5 | 140 | |

| GLC-50X53 | 19 | 2.6 | 3 | ± 0.2 | 3000 | 800 | 1.0X10-4 | 190 | |

| GLC-50X58 | 19 | 3 | 3 | ± 0.2 | 3000 | 800 | 1.1X10-4 | 215 | |

| GLC-55X57 | 25 | 3.2 | 3 | ± 0.2 | 3000 | 900 | 1.3X10-5 | 260 | |

| GLC-63X71 | 33 | 3 | 3 | ± 0.2 | 2550 | 1200 | 3.5X10-4 | 455 | |

| GLC -70X77 | 56 | 3.5 | 3 | ± 0.2 | 2500 | 1260 | 4.1X10-4 | 520 | |

Kopling Oldham minangka kopling poros fleksibel telung potongan sing digunakake kanggo nyambungake poros nyopir lan didorong ing rakitan transmisi tenaga mekanik. Kopling poros fleksibel digunakake kanggo nglawan misalignment sing ora bisa dihindari sing kedadeyan ing antarane poros sing disambungake lan, ing sawetara kasus, kanggo nyerep kejut. Material: Uubs ing Aluminium, awak elastis ing PA66.